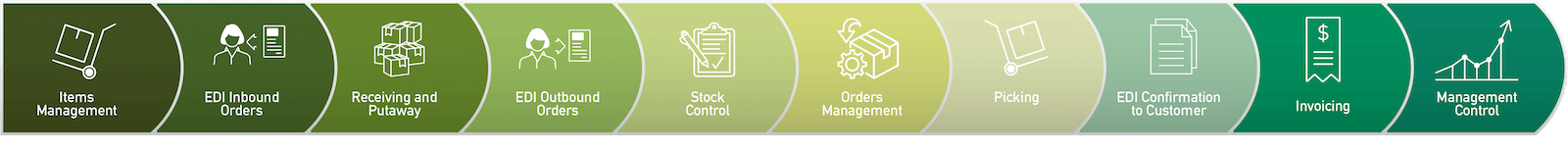

FOLLOW THE FLOW

LOGISTICS OPERATORS

Optimise your workflow

Simplify and optimise your warehouse operations?

It is possible thanks to BeOne WMS software, which can improve the work of logistics operators.

How?

Follow the flow to learn more about the innovations introduced by Nova Systems in the supply chain. An approach that aims to facilitate each stage, from the receipt of supplier orders to stock verification, through to invoicing and management control.

BeOne consists of a suite of integrated modules to enable a planning in order to support business growth. Starting with the CRM for the management of depositor rates, up to the shipment management, which can be created automatically thanks to the previously entered data.

Manuel Scortegagna, Managing Director of Scortrans, , and many other entrepreneurs and operators in the sector have already chosen the solution developed by Nova Systems.

Would you like to learn more about the BeOne logistics software?

Discover more!

Here is the workflow you can set up in the logistics operators' sector.

1 • ITEMS MANAGEMENT

The BeOne warehouse management software allows you to upload the depositor's item master data and specific operational details for each of the depositors. This can be done either manually or via BeOne's EDI (Electronic Data Interchange) system, used by operators to exchange data in electronic format. BeOne's features also allow for customised management of the specific operational particularities per item and item group.

2 • EDI INBOUND ORDERS

The warehousing software of BeOne has been developed to manage Supplier Orders, either by EDI or manual entry, to allow the operator to control each warehouse load. There is also the chance to manage, directly at the loading stage, the blocking of partial or the entire order for non-conformity. With WMS feature of BeOne, customisable one- and two-dimensional barcode labels can be produced, integrating management with radio frequency terminals to control the execution of loads. According to operational needs (area/allocation/item) TRF missions can be addressed to a generic operator, to a specific one or to several operators at the same time. Load to Warehouse missions can also be managed autonomously by the operator if authorised in advance. Further features are automatic and/or manual EDI reception of Supplier Orders and EDI sending of Supplier Order confirmation to the depositor.

3 • RECEIVING AND PUTAWAY

Thanks to this functionality developed in BeOne, it is possible to check the goods, palletise them, if necessary, send the depositor confirmation of receipt of the goods and generate TRF missions for the correct and efficient placement of the goods received. Also, in the case of managing warehouse loads, as in the case of receiving supplier orders, TRF missions can be addressed to a generic operator, to a specific operator or to several operators at the same time; Load-to-Warehouse missions can also be managed autonomously by the operator, if authorised. The functionality allows you to indicate, during the loading of goods, any exceedances of the threshold limits relating to fire loads and the Seveso Law.

4 • EDI OUTBOUND ORDERS

The management of customer orders can take place either in EDI mode or with user input. Real-time commitment of requested item quantities is also handled at this stage. The receipt of customer orders can be scheduled at scheduled times during the day or can be requested manually so that the operators are always in control of the workload to be carried out. The order fulfilment request date displayed on the screen allows you to keep the tasks to be always carried out under control for correct and timely planning.

5 • STOCK CONTROL

The BeOne WMS software makes it possible to interactively manage and query the stock of goods, both by dynamic and committed quantities. For goods that are committed, it is possible to immediately identify the Customer (outgoing) / Supplier (incoming) orders to which they refer. Item stocks can be queried either by goods total or by lot or variant detail, by allocation detail or by serial number.

Want to learn more about WMS software module for warehouse management?

6 • ORDERS MANAGEMENT

Once orders have been received, they can be analysed to identify the best solutions for their fulfilment, even identifying those that cannot be fulfilled or can be partially fulfilled. The BeOne features allow the creation of single or massive picking lists, identifying the best solutions for efficient management, such as grouping by delivery zones, by carrier used or by final destination.

7 • PICKING

Goods picks are driven by the missions that are processed at the request for the execution of the individual order or pick lists. TRF missions can be single or massive and can be differentiated between stock and picking missions. Also in this case, TRF missions can be addressed to a generic operator, to a specific one or to several operators at the same time, depending on operational needs. The functionality includes, if configured, the EDI sending of the customer order confirmation to the depositor.

8 • EDI CONFIRMATION TO CUSTOMER

In this phase of the flow, the necessary documents are produced, also on a customised layout of both the depositor and the receiver of the goods, with the option of managing the depositor's logos. Documents can be produced in PDF or XLS format. The BeOne WMS allows the data contained in the grid to be copied onto XLS sheets for further processing.

9 • INVOICING

One of the strengths of BeOne is the total integration between the various modules of the Suite. At this stage, integration with CRM allows the WMS to process the settlement of warehouse movements, with standard or special rates for individual depositors. The software allows tariff calculations to be made on the number of customer and/or supplier orders, order lines, occupied allocations, packaging material used, in addition to the classic calculation methods based on incoming and/or outgoing orders and stock of goods.

10 • MANAGEMENT CONTROL

Thanks to the BeOne WMS, it is also possible to manage inventories with radio frequency terminals in an integrated way. The feature enables the automatic identification of any inventory deviations and the automatic creation of the corresponding inventory adjustment entries. At this stage, it is possible to obtain indications, also of a graphical nature, regarding the progress of the inventory. Missions can also be managed autonomously by the TRF operator, if appropriately authorised. Provision is also made for the production, during the inventory mission, of an inventory label to be placed on the goods for easier identification of the goods already inventoried.